Simple and effective explanations from someone who has been at this for over 40 years, been to more than 300 industrial facilities in over a dozen countries, has been and still is a member of many NFPA committees, and has trained thousands all over the world. Money back guarantee, you will be pleased and see value!

25 Things You Will Learn

1. At least 5 things to consider before you start equipment and soon after it is started

2. How many times to try and light something off before stopping and getting help, a policy you should implement.

3. How to verify proper actuator operations, 10 things you should look at and consider.

4. Precautions for starting steam lines and avoiding water hammer.

5. Special care when it comes to opening and closing valves of any type.

6. Steam leaks and the special hazards they can pose.

7. What can happen when starting and stopping electric motors too frequently

8. Special considerations when making bolted connections, (fastener, gasket, and flange issues you may not have been aware of)

9. Understanding fasteners and the markings on them and why that’s important

10. Understanding lubricated plug valves and how to recognize obviously failed valves and what to do about it.

11. Techniques for evaluating pipe hanger issues, what to look for when you look up.

12. Awareness of piping corrosion hazards.

13. Understanding hazards associated with working on pressurized piping systems, why its very dangerous and what can happen.

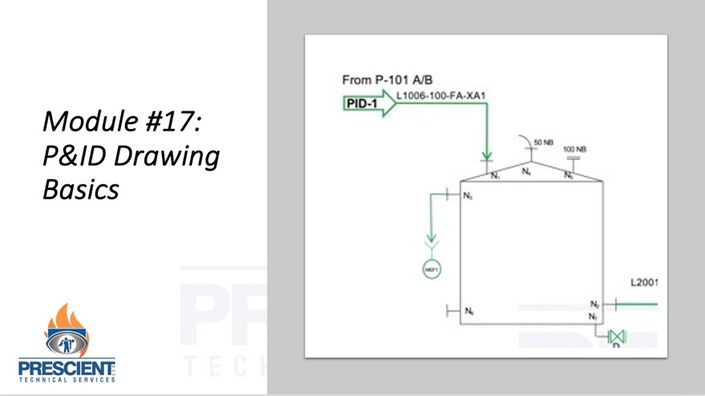

14. Understanding the capabilities of valves and components and what happen if the wrong components are used.

15. FRC (fire resistant clothing), how its rated, how to wear it properly, what its meant for.

16. Ten (10) ignition sources you may not have recognized before, you always have to assume one is around.

17. Lockout and isolation issues you may not have considered including 3 approved positive isolation techniques.

18. Purging and line breaking processes that can save lives.

19. Gas hazards and gas safety precautions including toxicity issues and how to protect employees.

20. Understanding how to observe flames and tell whether or not fuel air ratios are correct.

21. Understanding what burned paint might mean on the outside of a piece of fired equipment.

22. Some tips for identifying control system bypasses or jumpers within a panel that could save a life.

23. Simple technique that can help minimize risks when you open and electrical panel.

24. Noises and vibrations that can signal immediate trouble.

25. What control responses, (process variables), should look like over time, (understanding when there’s a problematic control loop response).

Example Curriculum - 83 Minutes of content, w/o quizzes

- Introduction & Module Layout

- 1. Start-Up Precautions (4:01)

- More help with starting up.

- 2. Verify Proper Actuator Operation (4:40)

- 3. Starting Up Steam Lines (2:17)

- Please Respect Water Hammer - It can be very dangerous! (3:00)

- 4. Don't Force Valves Open or Closed (2:42)

- 5. Operate Valves Carefully (1:02)

- 6. Not More Than 2 Start-Up Attempts (5:24)

- 7. High Pressure Leaks Can Be Deadly (2:33)

- Piping Repairs Could Be Dangerous - Even for Pro's

- 8. Bolted Connections Require Special Care (7:56)

- 9. Report Suspicious Threaded Piping (1:56)

- 10. Has the Steam Piping Moved? Still Supported? (1:24)

- 11. Corrosion Can Be a Big Killer (1:46)

- 12. Do You Have the Right Fittings? (1:04)

- 13. Don't Work on Energized Pressurized Piping Systems (2:50)

- 14. FRC Fire Resistant Clothing (1:42)

- 15. Ignition Sources You Never Thought About (1:27)

- 16. Lockout & Isolation, More Than One Closed Valve (5:40)

- Never trust valve handle positions

- 17. Line Breaking Can Be Trouble (2:12)

- 18. Purging Gases Requires Special Precautions (2:27)

- 19. Even a Small Nat. Gas Leak Can Be a Problem (3:19)

- 20. H2S & Nitrogen Can Kill Instantly! (1:35)

- 21. Control Loops Should be Snooth (1:33)

- 22. Bad Vibrations From Boilers & Equipment (3:11)

- 23. Electrical Panels Can Bite (1:56)

- 24. Boiler Flames Are Trying to Tell You Something (6:10)

- 25. Hot Spots & Smells Can Be Big Trouble (3:35)

- Quiz

Lessons learned using all the senses!

There are way more than 25 learnings here. This is an intense practical discussion based on things to see, hear, feel, know and even to smell. Any one item presented can save a life!