Simple and effective explanations from someone who has been at this for over 40 years, member of many NFPA committees, and has trained thousands all over the world. Money back guarantee, you will be pleased and see value!

20 Things You Will Learn

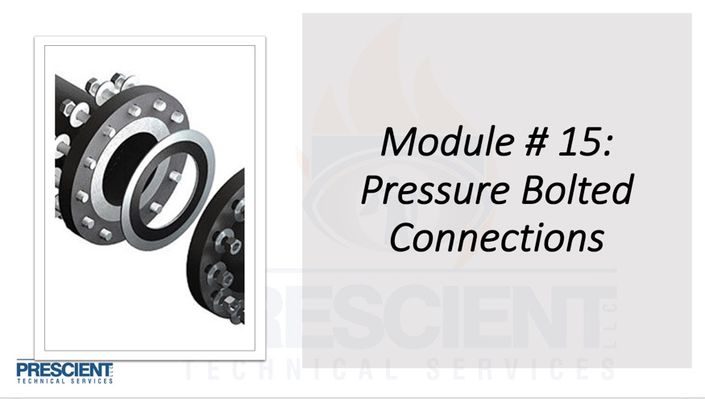

1. Description of pressure bolted boundary connections as a system, (fasteners, flanges, and gaskets).

2. ASME guidelines for pressure bolted boundary connections identified and discussed.

3. Explanation of fasteners and how they work and why they provide clamping force.

4. Fastener ratings and strength explanation, markings on fasteners explained

5. Mechanical properties of fasteners explained, yield strength/tensile strength and its significance.

6. Studs and how they are marked and the use of studs versus threaded rod

7. How to properly assemble a threaded fastener, things to check for.

8. Shear, torsion, tension, and compression stresses and how they impact fastener strength.

9. Looking at fasteners and understanding the failure mode.

10. The role of gaskets in proper joints, gasket material types

11. Five (5) important gasket selection factors

12. Understanding the language written on flanges and verifying that you have the right ratings and styles.

13. Flange grooves, how they seal, important issues surrounding cleaning them and knowing if they can be reused.

14. Flange alignment and hanger loadings and understanding how to assess the forces and factors that can make a flanged joint more successful and reliable.

15. Torques and torque sequences required for reliable joints, including considerations for washers and lubrication.

16. Tightening patterns and their importance and where to find them based on the job you are doing.

17. Bolted joint procedures, how to create them, examples, why they are important

18. Eight (8) factors for why bolted joints lose clamping force and fail.

19. Alignment techniques for spiral wound gaskets

20. Corrosion factors related to fasteners and flanges and how they impact clamping force.

Example Curriculum - 61 Minutes of content, w/o quizzes

Very Practical Learnings That Will Have Immediate Impact!

If you never learn that its the small grooves in the face of a raised face flange that actually have everything to do with making a flanged joint seal, you can't have a lot of respect for how to clean and what can be a problem on a flange face.