Simple and effective explanations from someone who has been at this for over 40 years, member of many NFPA committees including NFPA 54 "National Fuel Gas Code", and has trained thousands all over the world. Money back guarantee, you will be pleased and see value!

20 Things You Will Learn

1. The 4 different gas hazards that you should be aware of, pressure release, asphyxiation, flammability, and toxicity.

2. The difference between intentional released and non-intentional releases.

3. The two most important NFPA documents that address gas piping repairs and purging hazards.

4. The six steps to making safe gas piping repairs.

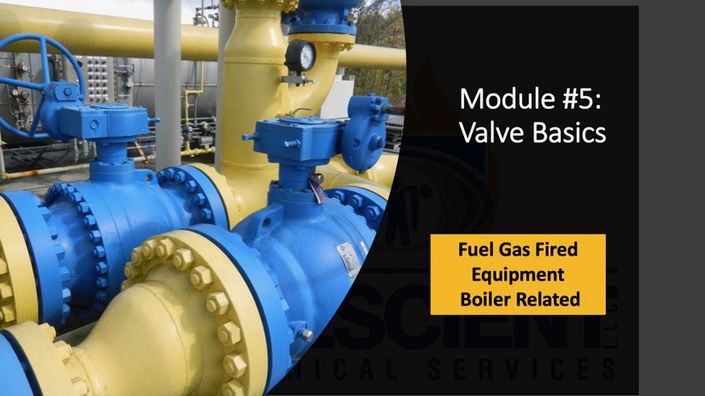

5. OSHA 1910 isolation techniques, (3 important approved techniques).

6. Isolation methods, positive and temporary.

7. Hazards that can occur when working behind one closed valve.

8. Six (6) important does and don’ts when working with valves.

9. How to recognize a lubricated plug valve, function test it, and seal it as is required by codes and standards and manufacturers maintenance requirements.

10. Line breaking hazards and six (6) different precautions that you can take to work more safely.

11. Venting versus purging of gas piping systems, what’s the difference?

12. The anatomy of a plume when gas is released, understanding threat zones.

13. Modelling tool, FREE, for understanding where released gas will go and how it can help you.

14. Three (3) considerations for where gas will go and why when it is released.

15. FRC, (fire resistant clothing), and how it is specified and how to avoid minimum requirements that can leave you with 50% body burns.

16. Range of flammability and the objective of purging.

17. A list of ten (10) ignition sources you may have never considered that could surprise you.

18. Pressure testing precautions, (pneumatic hazards and pressure release)

19. Three different types of purging processes, (slug, trickle, and pressure).

20. Post repair purging end points, nitrogen hazards, and re-introducing gas safely including meters and instruments to use.

Example Curriculum - 101 minutes of content, w/o quizzes

There's 4 Basic Gas Hazards that Can Harm or Kill!

Those conducting repairs or installing new gas piping systems need to understand all of the basic hazards that can occur from releases of gas. Making repairs to flammable gas systems is a unique piping job, special precautions have to be made. This presentation discusses these and provides a simple series of steps to minimize risks.